Menu

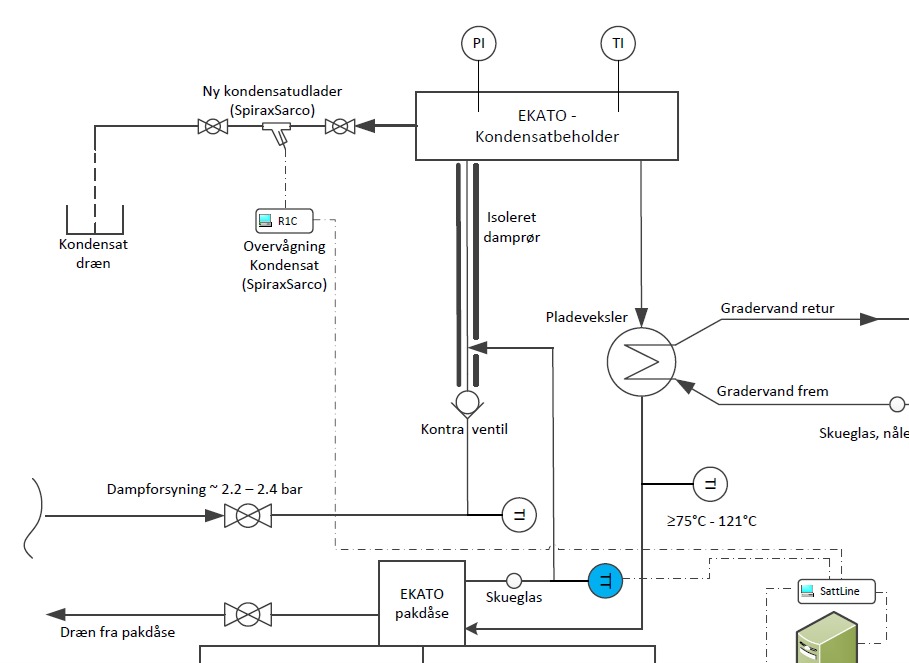

This task involves identifying and documenting the necessary mechanical requirements for the desired equipment or system.

CD stands for Conceptual Design, BD stands for Basic Design, and DD stands for Detailed Design. These phases involve developing conceptual ideas, basic design parameters, and detailed technical specifications.

Collaborating with the project team means working with engineers, designers, and other relevant stakeholders to ensure that mechanical requirements and design objectives are met.

This entails working closely with the production team and suppliers to ensure that the equipment is manufactured in accordance with the specified requirements and standards.

Approving production plans and identifying risks are important steps in this phase. Factory Acceptance Testing (FAT) is typically performed to verify that the equipment functions as expected before delivery.

This involves preparing the installation area and ensuring that it is ready for the installation of mechanical equipment.

Safety aspects must be taken into consideration to avoid accidents during installation.

The installation must follow strict instructions and design specifications.

Commissioning involves ensuring that the equipment operates correctly after installation.

SAT (Site Acceptance Testing) and IQ/OQ (Installation Qualification/Operational Qualification) are testing processes carried out to validate that the equipment meets the necessary requirements and specifications at the installation site.

This involves educating and training the individuals who will operate the mechanical equipment or system so that they can use it safely and effectively.

Creating and maintaining documentation, including technical specifications, manuals, and reports that describe the design, installation, and operation of the equipment.

This involves monitoring that the mechanical facility or equipment operates as expected after commissioning.

Any deviations or issues must be identified and resolved to ensure that the equipment meets the customer’s requirements and expectations.

These tasks are essential to ensure that mechanical systems or equipment meet the necessary requirements and standards while being safe and effective in operation.

As a mechanical engineer involved in a project, my responsibility includes defining mechanical requirements and collaborating with the project team to determine the design (CD/BD/DD). I conduct risk assessments to ensure that the requirements comply with relevant regulations, such as GMP and machinery safety.

During the manufacturing phase, I play an active role in approving production plans, aligning quality controls, identifying risks, collaborating with suppliers, and conducting equipment testing (FAT) in mechanical workshops. I am also responsible for the installation phase, ensuring that the installation area is prepared for machines and people, and all safety aspects are considered and followed according to instructions

As part of the project’s start-up phase, I take part in commissioning, SAT, and IQ/OQ procedures. Additionally, I provide training to users and handle documentation requirements. Throughout the commissioning process, I closely monitor the plant’s performance to ensure it meets the customer’s requirements and standards. My involvement ensures a smooth and successful execution of the mechanical aspects of the project

As part of the project’s start-up phase, I take part in commissioning, SAT, and IQ/OQ procedures. Additionally, I provide training to users and handle documentation requirements. Throughout the commissioning process, I closely monitor the plant’s performance to ensure it meets the customer’s requirements and standards. My involvement ensures a smooth and successful execution of the mechanical aspects of the project

RM Pharma Consulting is established by Rami Monem, a mechanical engineer with many years of GMP experience within project management and mechanical engineering.